Waterco's Role in Korea's First Specialized Land-Based Salmon Farming Complex With Wonjin Fisheries Co. Ltd.

Introduction: Breaking New Ground in Sustainable Aquaculture

As global demand for salmon continues to surge and wild catch supplies dwindle, the aquaculture industry faces mounting pressure to find sustainable, environmentally responsible solutions. Wonjin Fisheries Co. Ltd., a leader in South Korea's aquaculture sector, who provides consultation, design, installation, commissioning and after sales service, together with local council and engineering companies embarked on an ambitious project to address these challenges: the Pohang City Specialized Salmon Farming Complex, South Korea's first largescale land-based salmon RAS (Recirculating Aquaculture System) facility.

Waterco is privileged to contribute to this landmark development by providing the essential water filtration and pumping systems needed to operate under the demanding sea water conditions of a land-based aquaculture environment. With over 40 years of experience in water treatment engineering and a proven record in marine-grade solutions, Waterco’s role centres on ensuring operational reliability, water quality and long-term system performance.

Project Overview: Pohang City Specialized Salmon Farming Complex

• Location: Pohang City, North Gyeongsang Province, South Korea

• Project Cost: KRW 46.0 billion (approx. USD 32.0 million)

• Project Timeline: Test Bed started in December 2024; Completion targeted for December 2026

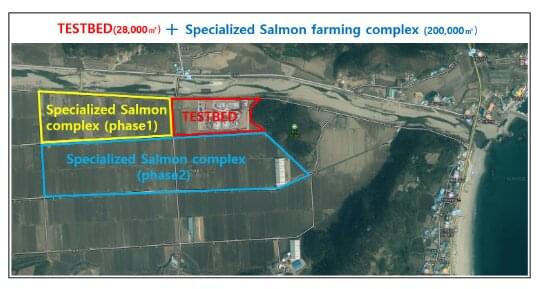

• Scope: Development of a 28,000m² Test Bed facility, with plans to expand to phase 1 and 2 of 200,000m² complex

The project marks a major step forward in Asia's adoption of RAS technology for large-scale land based salmon farming, promising better disease control, reduced environmental footprint and improved fish welfare and better yield.

Visualising the Future of Aquaculture: From Test Bed to Full-Scale Salmon Complex

Overcoming Industry Challenges with RAS Technology

Traditional open-net salmon farming methods are increasingly scrutinised due to their adverse impacts on the environment and marine life. These include pollution from waste, the spread of disease, sea-lice infestations, the escape of farmed fish that can disrupt wild genetic pools, and damage to the surrounding ecosystems.

RAS technology addresses these issues head-on by providing a closed-loop, controlled aquaculture environment. It significantly enhances biosecurity and disease management while mitigating environmental risks such as eutrophication. The system also eliminates the risk of farmed fish escape, preserving the integrity of wild populations.

While RAS is a proven technology in parts of Europe and North America, its large-scale application is still relatively novel in Asia. With the Pohang project, Waterco is proud to be part of the effort to advance this shift, supporting the region's transition towards more sustainable and responsible aquaculture practices.

System Operation Overview: How the RAS Test Bed Works

The Pohang facility’s land-based RAS is designed to replicate optimal marine conditions in a closed-loop environment, significantly reducing environmental impact. Large volumes of seawater are pumped into the system and first passed through sand filtration to remove suspended solids. The filtered water then enters a network of fish tanks, where the salmon are raised through various growth stages.

As the fish produce waste, the water becomes contaminated and become toxic to marine life. This contaminated water requires a carefully managed treatment process. This involves a combination of mechanical, biological and chemical treatment stages, which includes sand filters, drum filters, protein skimmers, moving bed bio-reactors (MBBRs), UV sanitisers , carbon dioxide stripper, water-to-water heat pump and oxygen injectors.

The treated water is then recirculated back into the tanks, minimising water consumption while maintaining a stable and healthy aquatic environment. This closed- cycle operation demands constant, high-reliability performance and control from all filtration and pumping systems—areas where Waterco’s engineering plays a vital role.

Early construction phase of the 28,000m² Test Bed, featuring reinforced tank structures. The biggest tank diameter is 21 meter with 6.5 meter height.

Pipe lines in progress

PE pipe joining

Waterco's Contribution: Engineering for Excellence

Wonjin Fisheries turned to Waterco for some components essential to the success of the Test Bed's intensive aquaculture operations. The project demanded products capable of handling large volumes of seawater under harsh, continuous operating conditions—a standard Waterco products are designed to handle with consistency and reliability.

Key Waterco Products Delivered:

Waterco supplied a suite of critical filtration and pumping systems specifically engineered for the challenges of landbased aquaculture. These included:

Micron Fibreglass Sand Filters:

• 3 units of MD6500 (4 Bar)

• 2 units of SMDD2000 (4 Bar)

Selected for their corrosion resistance, structural durability and ease of maintenance.

High-Performance Centrifugal Pumps:

Total pumps required for the Test Bed were 5 units of 230hp pumps and 110 seawater-compatible pumps (10–30hp range). Waterco supplied 50 units of Hydrostar MKIV 550 Marine Seal Pumps, chosen for their high efficiency and robust performance under continuous seawater operation.

These products were installed alongside other components forming the complete aquaculture system, including fish tank infrastructure, seawater pumping, water treatment and environmental control systems.

Together, the infrastructure supports 22 high-capacity fish tanks, operating with a total seawater volume of 20,000m³.

Meeting the Client’s Demanding Specifications

Wonjin Fisheries has uncompromising requirements for equipment selection, picking only systems that can endure high-salinity seawater, support continuous operation and deliver long-term efficiency. This is not just about buying parts; it is about choosing a technology partner who can meet the operational rigour of one of Asia’s most ambitious RAS developments.

Waterco’s products stand out for multiple reasons:

Built for Harsh Marine Conditions:

Waterco’s all plastic Hydrostar pumps are engineered specifically for seawater use, with materials and design features that withstand corrosion, reduce wear and maintain performance across high-load operations. The result is fewer breakdowns, less maintenance and more predictable output, which are all vital in a closed-loop aquaculture system.

High-Performance Filtration:

The supplied fibreglass filters are not only resistant to seawater corrosion but also designed with in-house proprietary boring processes for better sealing to prevent leakages , positive pressure manway seal, strong tripled gasket flange and lamination and a strong efficient backwash system to withstand the stress of frequent backwashing.

Ease of Integration and Maintenance:

From compact designs to straightforward installation and servicing procedures, Waterco equipment is built for integration into complex infrastructure. Such a feature is an important factor that enables smoother implementation and reduced downtime during setup.

Commercial Viability:

Just as critical as meeting technical demands is selecting solutions that align with the project’s commercial expectations. Waterco strikes that balance with a competitive price structure that aligns with the project's budget expectations.

Reliable Support Across Asia:

With local manufacturing capabilities and a well-established distribution network, Waterco is able to offer technical guidance, spare parts availability and ongoing after-sales service with minimal delays. This regional proximity and responsiveness are key to gaining the client's trust.

While Waterco is one of several contributors to the overall system, our scope focuses on the areas where durability, performance and continuous uptime are most critical—filtration and pumping. These are the lifelines of any land-based aquaculture setup, and it is essential that the solutions meet the highest operational standards.

Pictured during the factory visit are Waterco’s Mr. Goh Soon Sinn (second from right), and his wife, Mr. Steven Liew (third from left), and Mr. Lee (far right) President of Wonjin Fisheries, together with the Wonjn Fisheries engineers

1200mm diameter PE pipe & Wonjin engineering team headed by Engineer Lee (second from right)

Conclusion: Waterco—Your Trusted Partner in Aquaculture Innovation

At Waterco, we are committed to engineering solutions that empower sustainable growth in aquaculture. Our involvement in the Pohang City Specialized Salmon Farming Complex demonstrates our ability to deliver highperformance products and strong after-sales support for demanding, large-scale projects.

As the Pohang Test Bed progresses towards its 2026 completion, Waterco remains gratified to contribute to shaping a future where aquaculture thrives responsibly, efficiently and sustainably.

Waterco Far East Sdn. Bhd.

Lot 832, Jalan Kusta

Kawasan Perindustrian SB Jaya

47300 Sungai Buloh

Selangor Darul Ehsan, Malaysia

Telephone: +60 3 6145 6000

Download: Wonjin Pohang SK Case Study.pdf